For detailed information, other images and documents, please select individual articles from the following table.

CUT+COOL Eco drilling and cutting oil

Biodegradable cutting oil

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

Call customer service: (23) 418-130

Prices for customers after login

Aerosol can with ECO-Stop technology

- Up to 2500 applications possible due to predefined quantity per valve operation

- Minimal smoking

Easy to use

No cleaning of metals prior to installation or further treatment (e.g. welding) required with low usage concentrations

Neutral behaviour

- Contact with sensitive materials (e.g. marble, plastic and electrical components) possible

- Odourless

Oil-soaked cleaning cloths should only be stored in non-flammable, self-sealing, tightly sealed, and appropriately labelled containers (BGI 560).

| Drilling and cutting oil | Drilling and cutting oil Perfect | Drilling and cutting paste Perfect | Drilling and cutting oil Eco | Drilling and cutting foam | Cutting oil DVGW | Coolant Ultra | Coolant Ultra HD | |

| Materials | ||||||||

| Machining processes | ||||||||

| Features | ||||||||

| Base material | Mineral oil | Mineral oil with synth. Ester | Mineral oil with synth. Ester | Synth. Ester | Glycol and ester | Ester | Mineral oil | Mineral oil |

| Steel, alloyed steel | xx | xxx | xxx | xxx | xxx | xx | xx | xxx |

| High-alloy steel | xx | xxx | xxx | xxx | xxx | xx | xx | xxx |

| Cast iron, grey cast iron | xx | xxx | xxx | xx | xxx | x | xx | xxx |

| Carbide | xx | xxx | xxx | xx | xxx | x | x | xx |

| Non-ferrous base metal (copper, brass etc.) | xx | xxx | xx | xxx | xxx | x | x | xx |

| Titanium | x | xxx | xxx | xx | xxx | x | x | xx |

| Magnesium | x | xxx | xxx | xx | xxx | x | x | xx |

| Aluminium, aluminium alloys | x | xxx | xxx | xx | xxx | x | xx | xxx |

| Turning, turning machines | xx | xxx | x | x | x | x | xx | xxx |

| Drilling, countersinking, reaming | xx | xxx | xxx | xxx | xxx | x | xx | xx |

| Deep drilling | x | xxx | xxx | xx | xx | x | x | xx |

| Sawing | xx | xxx | xx | xxx | xxx | x | xx | xx |

| Thread cutting | xx | xxx | xxx | xxx | xxx | xx | xx | xx |

| Thread moulding, rolling | xx | xxx | xxx | xxx | xxx | x | x | xx |

| Milling | x | xxx | x | xx | xx | x | xxx | |

| Sanding | x | xxx | x | x | x | x | xxx | xx |

| Forming, rolling, bending | x | xxx | xx | xx | xx | x | x | xx |

| Punching, fine punching | x | xx | xx | xx | x | x | x | |

| Broaching, toothing | x | xxx | xx | xxx | xxx | x | x | x |

| Viscosity (mm²/s) | 12 | 25 | Paste-like | 35 | n/a | 5 | 66 | 76 |

| Minimum quantity lubrication | ⎷ | ⎷ | ||||||

| Free from mandatory warning symbols | ⎷ | ⎷ | ⎷ | ⎷ | ||||

| Can be used upside down | ⎷ | ⎷ | ||||||

| DVGW-approved | ⎷ | |||||||

| Biodegradable/approved for use with food | ⎷ | |||||||

| Extremely high lubricating performance | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | |||

| Extremely long tool life | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ||

| Minimal smoke formation | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ||

| Extremely low consumption | ⎷ | ⎷ | ⎷ | ⎷ | ||||

| Good creeping properties | ⎷ | |||||||

| Free of boric acid | ⎷ | ⎷ | ⎷ | ⎷ | ||||

| Low-foaming | ⎷ | ⎷ | ||||||

| Extremely high microbial stability | ⎷ | ⎷ | ||||||

| Water hazard class | 1 | 1 | 1 | 1 | 2 | 1 | 1 | 1 |

| Formaldehyde-free | ⎷ | ⎷ | ⎷ | ⎷ | ||||

| Extremely gentle on the skin (amine-free) | ⎷ | ⎷ | ⎷ | |||||

| xxx excellent suitability xx good suitability x less favourable suitability ⎷ applicable | ||||||||

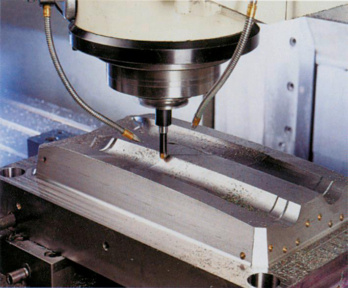

For use on-site, with loss lubrication and in food-contact areas. Ideally suited for use with surface pressures between the workpiece and tool and for all complex machining operations. Can be used for shaping steel, aluminium and non-ferrous heavy metals.

No cleaning of metals before assembly or further treatment (e.g. welding) is required for low application concentrations. The product is processed as delivered.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!