Plastic frame anchor W-UR 14

Plastic frame anchor, W-UR 14

ANC-(W-UR14)-PLA-40-14X140

Art.-no. 0912814003

EAN 4052712295300

Register now and access more than 125,000 products

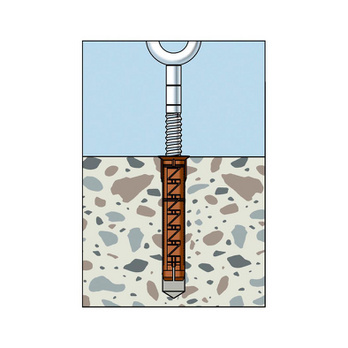

- Fast, precise and stable installation due to precisely fitting frame fixing

- Time savings due to immediate load-bearing capacity

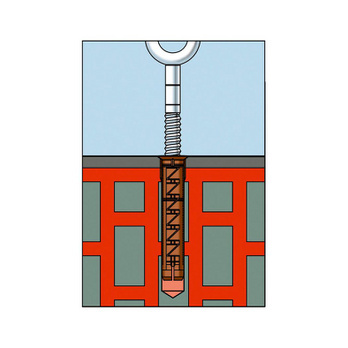

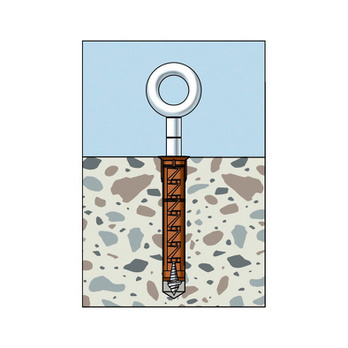

- Suitable for removable anchorage

- Optimal fastening of façade scaffolding, staging, scaffolding systems etc.

- Test loading must be conducted at each place of use, in accordance with German safety regulation BGI/GUV-I 663, item 4.6.3. When anchoring in solid brick and solid sand-lime block, we recommend performing pull-out tests due to differences in brick manufacturing.

- Anchorage design is not required up to the verified window size for the tested surfaces and the appropriate installation

Datasheets(X)

- Suitable for W-GS SymCon eye bolt for scaffolding

- Anchors may be used for one-off temporary anchoring of façade scaffolding with a service life of < two years

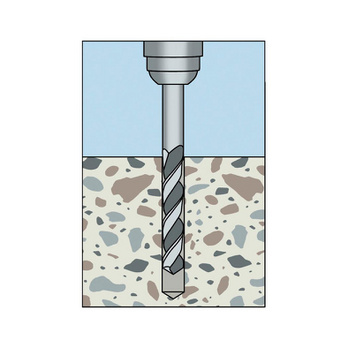

- Suitable for anchoring in normal weight concrete masonry walls such as solid brick, solid sand-lime blocks, vertically perforated brick, hollow sand-lime blocks, hollow lightweight concrete blocks, solid lightweight concrete blocks, concrete bricks

- Suitable for fastening façade scaffolding, staging, scaffolding systems etc.

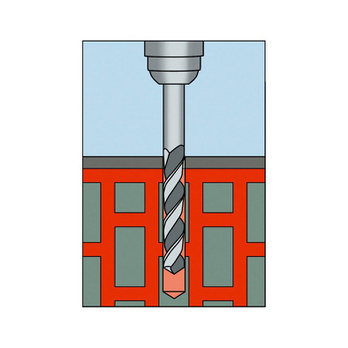

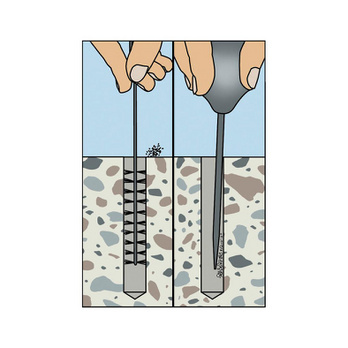

- Drill perforated and hollow concrete blocks with a rotary drill (without hammer mechanism)

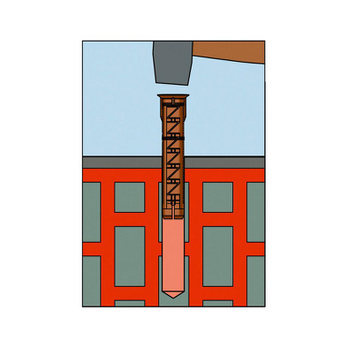

- Drill cuttings must be removed from the drill hole

- Installation temperature in base material ≥ -20 °C

- Installation temperature of the anchor sleeve ≥ 0 °C

Anchor diameter | 14 mm |

Anchor length (l) | 140 mm |

Max. attachment height (t fix) | 40 mm |

Nominal drill-bit diameter (d 0) | 14 mm |

Type description | W-UR 14 |

Performance data: Concrete, Anchors in a redundant non-structural system | |||

Anchor diameter | [mm] | W-UR 14 SymCon | |

Embedment depth of the anchor sleeve | hnom [mm] | 100 | |

| Centric tension load1) for individual anchors or an anchor group | Nadm = C12/15 [kN] | 30°C2)/50°C3) | 2.4 (2.1)4) |

| 50°C2)/80°C3) | 2.4 (2.1)4) | ||

| Nadm ≥ C16/20 [kN] | 30°C2)/50°C3) | 3.2 (2.1)4) | |

| 50°C2)/80°C3) | 3.2 (2.1)4) | ||

| Minimum member thickness | hmin | [mm] | 140 |

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of γF = 1.4 have been taken into account. For information on combining tensile and shear loads, please refer to ETAG 020 Annex C 2) Maximum long-term temperature 3) Maximum short-term temperature 4) Number of attachment points = 3 and at least 1 anchor per attachment point results in a load per attachment point of Nadm ≤ 2.1 kN or number of attachment points ≥ 4 and at least 1 anchor per attachment point results in a load per attachment point of Nadm ≤ 2.4 kN or 3.2 kN (depending on concrete strength and temperature range). | |||

Performance data: Masonry4), anchors in a redundant non-structural system (temperature range 50°C2)/80°C3)) For other brick types, raw densities, minimum compressive strengths, edge and axis distances or temperature ranges, please refer to the approval ETA-11/0309 | ||||

Brick type | Brick format [mm] | Raw density class [kg/dm3] | Minimum compressive strength [N/mm2] | Nadm [kN] 1) 5) (centric tension load for individual anchors) |

Effective anchorage depth | hnom [mm] | 100 | ||

Masonry brick Mz, EN 771-1, DIN 105 | ≥ 3DF (≥ 240 x 115 x 113) | ≥ 1.8 | 10 | 1,0 |

| 20 | 1,57 | |||

Solid sand-lime brick Silka XL Basic, Silka XL Plus, EN 771-2, DIN 106, Z-17.1-997 | ≥ NF (≥ 248 x 175 x 498) | ≥ 2.0 | 10 | 0,86 |

| 20 | 1,29 | |||

| 28 | 1,86 | |||

Normal weight concrete solid brick Vbn, EN 771-3, DIN 18153 | ≥ NF (≥ 240 x 115 x 71) | ≥ 2.0 | 10 | 0,57 |

| 20 | 0,86 | |||

| 28 | 1,14 | |||

Normal weight concrete solid brick V, EN 771-3, DIN 18152-100 e.g. BisoBims Classic, Bisotherm | ≥ 3DF (≥ 240 x 175 x 113) | ≥ 2.0 | 10 | 1,14 |

| 20 | 1,57 | |||

Lightweight concrete solid brick V, EN 771-3, DIN 18152-100 e.g. BisoBims | ≥ NF (≥ 240 x 115 x 71) | ≥ 1.0 | 2 | 0,34 |

| 4 | 0,57 | |||

Vertically perforated brick HLz6), EN 771-1, DIN 105 e.g. Wienerberger, Schlagmann | ≥ 12DF (≥ 373 x 240 x 238) | ≥ 1.2 | 6 | 0,43 |

| 8 | 0,57 | |||

| 10 | 0,71 | |||

Vertically perforated brick HLz T14-24.06), EN 771-1, Z-17.1-651 e.g. Wienerberger | ≥ 10DF (≥ 308 x 240 x 249) | ≥ 0.7 | 6 | 0,17 |

Vertically perforated brick POROTON T8-306), POROTON T9-306), EN 771-1, T8: Z-17.1-982, T9: Z-17.1-674 Wienerberger, Schlagmann | ≥ 248 x 300 x 249 | ≥ 0.6 | 6 | 0,43 |

| 8 | 0,57 | |||

Hollow sand-lime brick KSL6), EN 771-2, DIN 106-1 e.g. Xella | ≥ 8DF (≥ 249 x 240 x 238) | ≥ 1.4 | 6 | 0,34 |

| 8 | 0,43 | |||

| 10 | 0,57 | |||

| 12 | 0,71 | |||

Hollow concrete block of lightweight concrete 3K Hbl, EN 771-3, DIN 181516) e.g. Liapor | ≥ 16DF (≥ 498 x 240 x 238) | ≥ 0.7 | 2 | 0,14 |

| 4 | 0,26 | |||

| 6 | 0,43 | |||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of γF = 1.4 have been taken into account. For information on combining tensile and shear loads, please refer to ETAG 020 Annex C 2) Maximum long-term temperature 3) Maximum short-term temperature 4) For other brick types, raw densities, minimum compressive strengths or temperature ranges, please refer to the approval ETA-11/0309. 5) The brick geometry should be compared with the approval ETA-08/0190. 6) If the drill hole is created through impact or hammer action, the admissible load must be determined by tests on the structure. | ||||