Filler VAKU 70

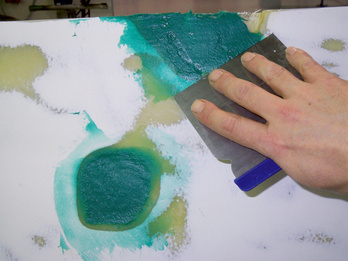

Filler, VAKU 70

FILR-GF-(VAKU-70)-1800G

Register now and access more than 125,000 products

Balanced proportion of glass fibres

- Excellent application properties

- User-friendly

Excellent adhesion and stability

- Highly suitable for use on vertical surfaces

- Superb adhesion to iron, steel, aluminium, galvanized and hot-dip galvanized surfaces.

- Ideally suited as knifing filler after repairing GFRP parts with VAKU 80 repair resin.

Fast curing

- For fast, time-saving further processing.

Maximum permissible VOC content of VAKU 70: 250 g/l of product category 2(b). Max. VOC content in accordance with German Ordinance on Solvent-Based Paints and Lacquers (ChemVOC FarbV): 4 g/l.

Heat-resistant up to 80°C

Tip: Can be coated with VAKU 20, VAKU 30 and VAKU 40 filler without sanding in between coats. To prevent possible complaints, always ensure that the correct dosing ratio of filler to hardener is used.

Datasheets(X)

Auto/cargo: In vehicle construction and vehicle repairs for levelling unevenness, cracks and holes. For repairing glass fibre reinforced plastics. Attachments on trucks and passenger cars.

Metal: In machines and steel construction for levelling out larger damaged areas. For repairing glass fibre reinforced plastics.

The surface must be clean, dry and free from grease. Sand surfaces. Wherever possible, only sand polyester material when dry due to its sensitivity to water. See separate information on wet sanding.

Contents | 1120.8 ml |

Smell/fragrance | Characteristic |

Weight of content | 1760 g |

Conditions for VOC concentration | ChemVOCFarb |

Chemical basis | Polyester resin |

Colour | Green |

Hardener content | 2 % |

Density | 1.606 g/cm³ |

Max. working life | 5 min |

Min. working life | 4 min |

Conditions for working life | at 20°C |

Conditions for drying time | at 20°C |

Min. drying time | 20 min |

Max. drying time | 30 min |

Max. temperature resistance of the hardened material | 80 °C |

Max. permissible VOC concentration | 250 g/l |

Max. VOC concentration | 4 g/l |

Shelf life from production | 12 Month |

Included in delivery | 1760 g filler, 40 g hardener, plastic spatula |

Additional articles | Sandpaper Useit, art. no.: 05813... |

Just leave the field empty if you don't know the packaging unit when directly entering the article number in the shopping basket or when importing with v

VVVV = 4 digits for prefix number (please note that the first digit is currently always 0)

AAA = 3 digits for dimension part 1

BBB = 3 digits for dimension part 2

Example article number structures:

Example 1: Screw with dimensions of 4x10 mm:

VVVVAAABBB

00574 10 (2 spaces between the 4 and the 10)

Example 2: Screw with dimensions of 10x20 mm:

VVVVAAABBB

005710 20 (1 space between the 10 and the 20)

Example 3: Flat washer with an internal diameter of 6 mm:

VVVVAAABBB

04076

The displayed price is always in line with the displayed packaging, if the PU is 250 the price for 250 units, if the PU is 300 the price for 300 units.

Price with price key representation (PSL):

The price always applies to a quantity ruled through the price key:

Price for 1 unit

Price for 100 units

Price for 1000 units

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!